AUTOMOTIVE Tier1 supplier

Automotive / Logistics systems |

|

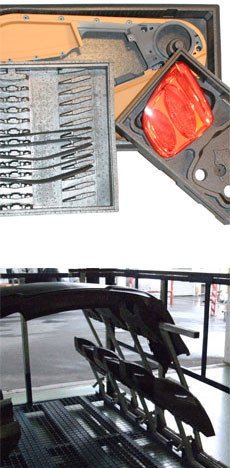

Carriers |

Grupor® carriers are manufactured exactly in accordance with the specific dimensions and properties of the parts to be transported. They are light but extremely stable and durable. They facilitate the transport of parts between manufacturers and processors, reduce costs and simplify handling when installing the parts. Grupor® carriers can be precisely foamed up to a size of 3850 X 800 X 315 mm from a mould. Grupor® carriers and part pick-ups for universal and special bearings, a guaranteed hit in every logistics concept. As a ISO/TS 16949/2009-certified company we guarantee that your orders are executed and processed in a reliable way.

Last but not least:

Carriers made of Grupor® granulated foam plastics not only protect your goods, they also reduce fuel consumption and CO2 emissions from lorries considerably.

Solutions for logistics systems

Carriers protect and ensure optimal transport

Modern logistics concepts require, secure, reusable, light and manageable transport and packaging systems. Grupor® carriers combine all these attributes and have clear advantages compared with conventional packaging systems.

Highlights Grupor® carriers

- Short development times

- Affordable and produced quickly

- Precise absorption and optimal protection of sensitive parts such as mouldings, chrome or long, unstable parts

- Dimensions up to 3850 X 800 X 315 mm from a form

- Robot-compatible during the manufacturing process

- Stackable with manual interventions- Can be labelled

- As a reusable (EPP) or disposable solution (EPS) also anti-static

- Dust-free closed off to the outside

- Environmentally-friendly

Thanks to its extremely robust structure, Grupor® carriers have an above-average operating life. Each part is optimally protected due to a combination of different granulated foam plastics. True to the saying “tough on the outside – soft on the inside“, scratch-sensitive parts are protected by a highly compressed box made of EPP with a soft EPE insert.

If larger parts need to be transported, this is done using special carrier systems. To that end, the plastics plant in Katzbach foams parts reception in all versions, which are placed in lattice boxes, for example.

Unlike conventional packaging, foamed carriers are used for years on end, can be easily transported and are therefore environmentally friendly. Grupor® carriers can be fully recycled at the end of their period of use.

Speed is our strength.

Packaging solutions from the concept right through to series production are quickly implemented

Whether chrome trim, painted parts or heavy elements made of metal, we find the optimal packaging solution tailored to your product. Our specialists can design your carriers within a short period of time using sample parts of CAD data. A prototype is milled immediately or built by hand as part of in-house prototyping. Once your approval has been obtained, the series tool, in turn, is created during the in-house moulding process. Changes can be carried out at short notice thanks to our high level of manufacturing penetration.